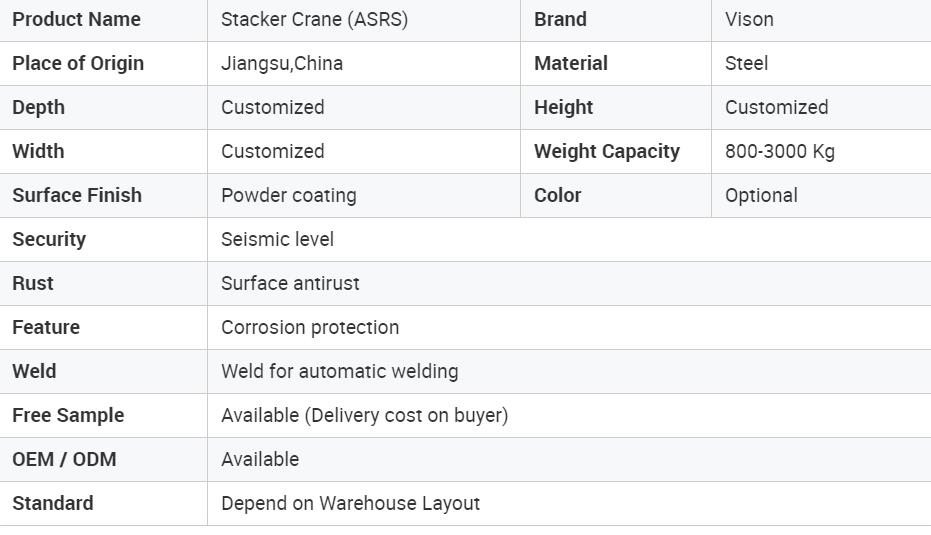

Stacker Crane racking system (ASRS)

ReturnCrane-in-Aisle Storage & Retrieval systems that utilize storage retrieval (SR) crane.

Features

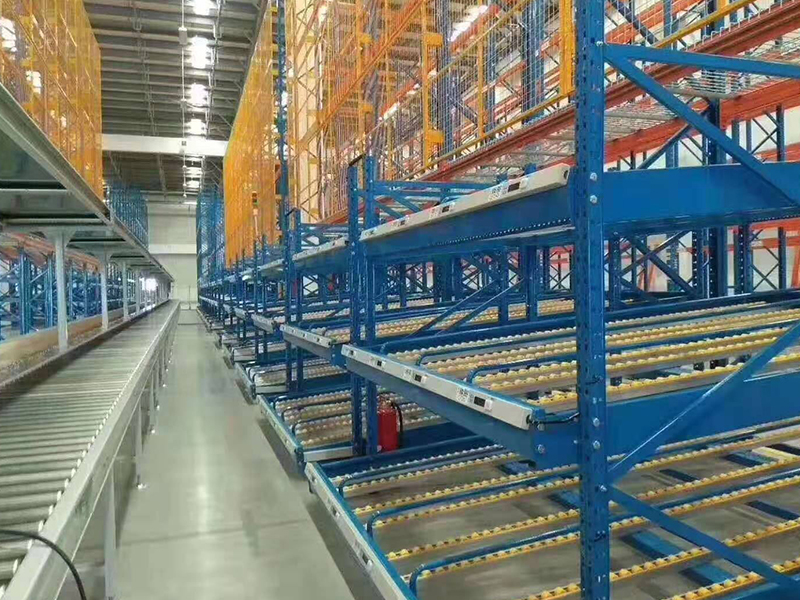

1. Racking Structural feature: ASRS System are usually equipped with pallet racking and drive-in racking, both of which are composite structure. Steel panels and wooden panels are available for loading with good capacity. Conveyors will do the loading and unloading job under the instruction from the central computer. ASRS System is mainly used in the food, tobacco, electronic, mechanical and armament industry.

2. Stacker Structural feature: Double upright structure, steady and reliable, vector frequency conversion drive and encoder position control, mechanical and electronic safety devices to ensure safe using of the system; All the way tracing technology by information transferring; Electric components are imported from abroad; Touching screen interface for easy operation; Making manual, semiautomatic, automatic and linkage control come true; Used in many situations by combining with other logistics equipment.

3. Conveying system Structural feature: Conveying system is usually equipped in the front or back of warehouse for conveying goods here and there, bridging the procedures done by forklifts and stackers by using rolling conveyor or chain conveyor and combining with lifts, rotating devices and other equipments.

4. Controlling system Structural feature: Communicating with WMS and ECS through OPC agreement, PROFIBUS bus network, set up by Siemens S7-300 controller can operate all conveyors offline, doing conveying of goods automatically. Please refer to the attached drawing for details of conveying system

5. WMS System Hardwares of WMS System: Star network structure, network sever, RF server, computers for management and monitor, RF base station and RF terminal for in/out warehouse of goods. Softwares of WMS System: Operating system: WINDOW 2000X SEVER Data-base: MS SQL SEVER 2000X Warehouse management software: WMS Equipment controlling software: ECS Bar code management software: RF

- ← Prev: Pallet Shuttle Rack

- Next →: ASRS racking system