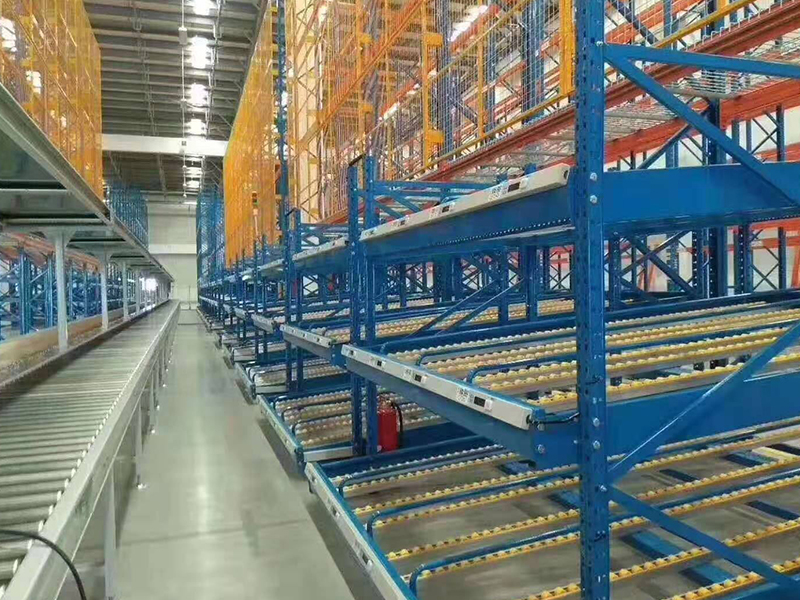

Carton flow rack

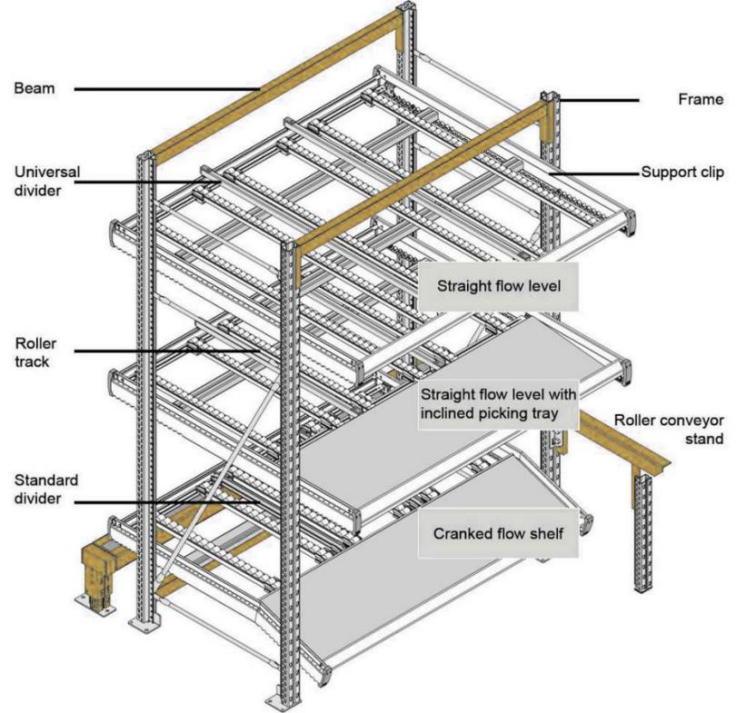

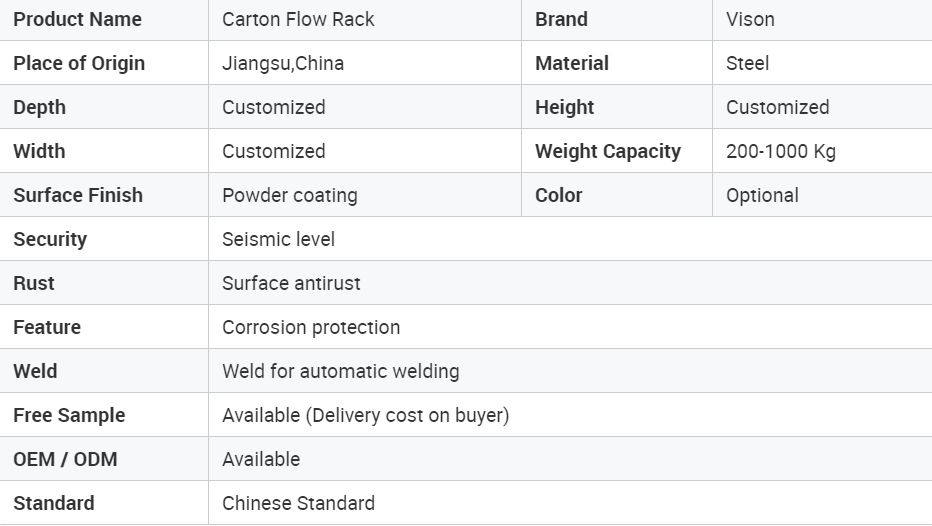

ReturnCarton flow rack improve visibility and order accuracy with its tilted shelves, it is the perfect answer for split case or piece picking. The racking is developed from the medium duty racking. Aluminum or steel roller rail are equipped between a pair of beams per layer to form a slope of 3 degree, and under the driven of gravity, product moved from the loading side to the picking side of the rack, "first in first out" of goods are realized. The height of the racking is normally lower than 2.5M and the loading capacity of each layer is 1000kg at the most. Shelves can also be adjusted to meet your picking height requirements.

Request information or get a quote

Description

Features

1.Unique aluminium or steel roller rail system which cartons move smoothly to the other side.

2.FIFO( first in first out) realized.

3.Flexible design on size and structure according to box or carton size.

4.Dramatically improve warehouse efficiency.

5.Keep labor cost down.

6.Convenient access for two sides of assembly line.

7.Perfect for warehouse slit case or piece picking.

- ← Prev: Drive in rack

- Next →: Cantilever Rack